China CNC Machining Services – What Criteria to Consider Before Purchasing

The main reason that overseas customers choose China as their source for CNC machining parts is cost reduction. Most companies that located close to industrial centers can directly order the parts from local workshops nearby. So they don’t need to wait a long time for freights from China and to deal with import costs and bureaucracy.

However, the cost savings can be very significant if the annual purchasing volume is high. That is the reason many companies are very interested in locating new suppliers and ordering CNC custom-made parts from China.

The criteria to consider before purchasing CNC machining parts from China are:

- Type of raw materials

- Manufacturing capacity

- Quality control and inspection measures

- Factory location

- The complexity of the parts

- Standards

- Incoterms/Shipping terms

- Payment terms

- Production time

- Shipping time

Type of raw materials

Aluminum is the most popular material for CNC machining because of its properties. It doesn’t require to change of cutting tools often, and the machining process is fast. Besides Aluminum, there are many kinds of materials used in the CNC machining industry, such as steel, brass, titanium, copper, and plastic materials.

An important point to check is whether the Chinese raw materials suitable for your project and if there are requirements to use original materials that meet US/ European standards or others. It has an impact on the cost of the parts because imported metals are quite expensive in China.

The main factors to consider when selecting a material for CNC parts are machinability, compatibility, working environment, weight, price, corrosion resistance, strength, finish, and appearance. There are hundreds of metals and alloys that can be used for the production of CNC machining parts.

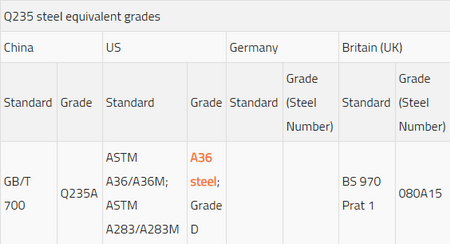

For example, see a table of equivalents grades for A36 Steel:

Manufacturing capacity

The estimated volume of orders should match with the manufacturer’s size. If you have demand for large quantities, then choose a supplier that has enough machines to support the requirements. Whereas if you need small quantities you should choose a small factory that is willing to produce small batches.

The CNC machines can keep running day and night so you can calculate the total production capacity (machine-hours) according to the number of machines.

Quality control and inspection measures

The mechanical engineers designing machining parts usually require high precision tolerances. It depends on the application, assembly, and other factors. Consequently, CNC machining manufacturers have to inspect the parts with advanced measuring equipment.

Check what testing equipment the factory has and how they apply quality control procedures during production.

Factory location

China is enormous plus you can find CNC machining suppliers almost everywhere. It is important to check the exact location of the factory, and what are the distances to seaport and airport. The transportation costs in China depends on the distance of the factory to ports.

Also, if you purchase other items from China and want to combine shipments then it is better to choose in advance factory in the same area.

China has 34 major ports and more than 2000 minor ports. List of Port in China (Wikipedia).

The complexity of the parts

The CNC machines with 3-axis (X, Y, Z) are probably still the most widely used equipment to create mechanical parts.

However, you may need a 5-axis machine for very complex parts. 5-axis machine can rotate on two additional rotary axes and approach the part from all directions.

Standards

Verify that the Chinese supplier complies with ISO standards, which confirm they follow QC methodologies and the production quality is high and stable.

Incoterms/Shipping terms

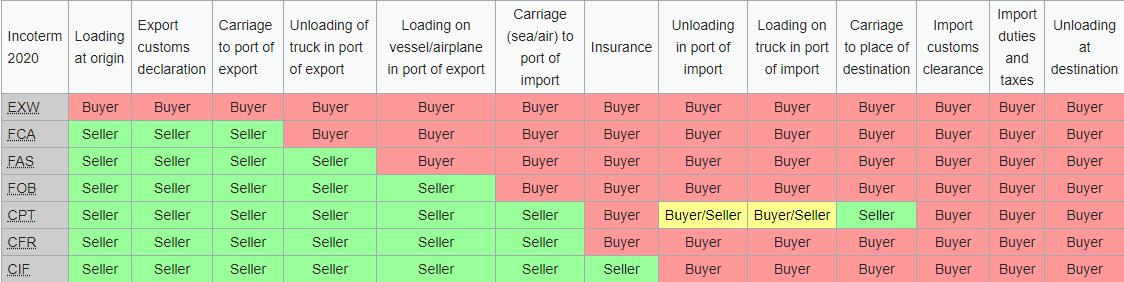

The common shipping terms are EXW, FOB, and CIF.

EXW (Ex-works)– The buyer is responsible for the whole shipment from door to door.

FOB (Free On Board) -The price for goods includes delivery at the shipper expense to a specified airport or seaport.

CIF (Cost, Insurance, and Freight) – The expense paid by a shipper to cover the costs, insurance, and freight against the possibility of loss or damage to goods while it is in transit to the destination port.

Check what the shipping terms of the manufacturer are

because it affects the logistics and shipping costs.

Payment terms

The payment terms of domestic suppliers are usually net 30

or net 60. However, for international trade, the payment term is normally a 30%

down payment and a 70% balance payment.

Most suppliers in China require a 30% deposit for purchasing

the raw material. After shipment, the factory sends a copy of the bill of

lading to the customer for balance payment.

Production time

The production time depends on the batch size, materials

availability, part’s complexity, and also how busy is the manufacturer. So make

sure to confirm the production time in advance and if it’s too long then better

choose another supplier who offers shorter lead times.

In general, the production time for CNC machining parts is

15-25 days. As CNC machining parts don’t require special molds, the

manufacturer can start production immediately once the raw material is ready.

Another factor to consider is the production time of first-order versus repeated orders. As these are customized parts, the production time is longer when the factory produces it for the first time. In the repeated orders, the process will be more efficient and smooth with possibly shorter delivery times.

Shipping time

You can ship the parts from China with a courier company,

air freight or sea freight. The courier companies such as DHL, FedEx, or TNT

ship parcels within 3-10 days. They offer door to door service with express and

economy services.

Airfreight takes 4-7 days and mostly depends on booking space

based on availability and prices of flights. It is suitable when you need the

goods fast but the cargo size or weight above the limits for courier delivery.

Sea freight takes 15-35 days and depends mostly on the destination

port and sea freight type, FCL or LCL. Usually, FCL is faster than LCL due to

less overall handling.

However, the delivery times above are only an estimation and

not guaranteed, especially for sea freights. Sometimes, there are unexpected

delays of customs clearance, availability, strikes in port, and more.